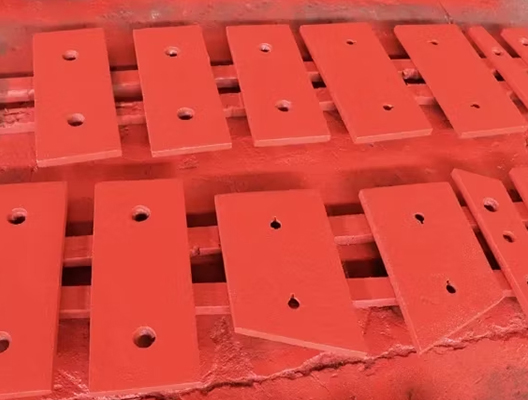

Blow Bar Gallery

Material Option

Composite materials are increasingly used for impact crusher blow bars due to their superior wear resistance achieved by combining hard materials within a tougher matrix, leading to longer lifespan and reduced maintenance.

We offer blow bars by different composite materials as following:

| Classification | Recommended for |

| High Chrome Ceramic (K650 HCC) |

Secondary crushing level with natural stone or gravel; Asphalt with smaller feed size and without any metal content. |

| Medium Chrome Ceramic (K600 MCC) |

The application falls between Martensitic and high chrome. Extended wear life |

| Toughed Medium Chrome Ceramic (KT600 MCC) |

The application falls between medium chrome and Martensitic the conditions for the recycling of building materials and concrete, and with smaller feed size. |

| Martensitic Ceramic (K550 LCC) |

Recycling of building materials and concrete with little to medium iron content; asphalt recycling; natural stone. |

| Manganese with TIC (K200 HM TIC) |

Crushing limestone in cement plants. |

Looking For A Quick Contact?

We understand that customers typically require more than just wear parts; they also need to replace other spare parts on their crusher equipment. To offer customers a one-stop service, we strive to list all available product part numbers on our website. If you cannot find the required part, please use the contact form on the right to reach out to us promptly.

Note: Without technical drawings, we can only provide accurate quotations for both wear parts and spare parts based on the part number. Kindly ensure the part number is provided when submitting your inquiry.