C100

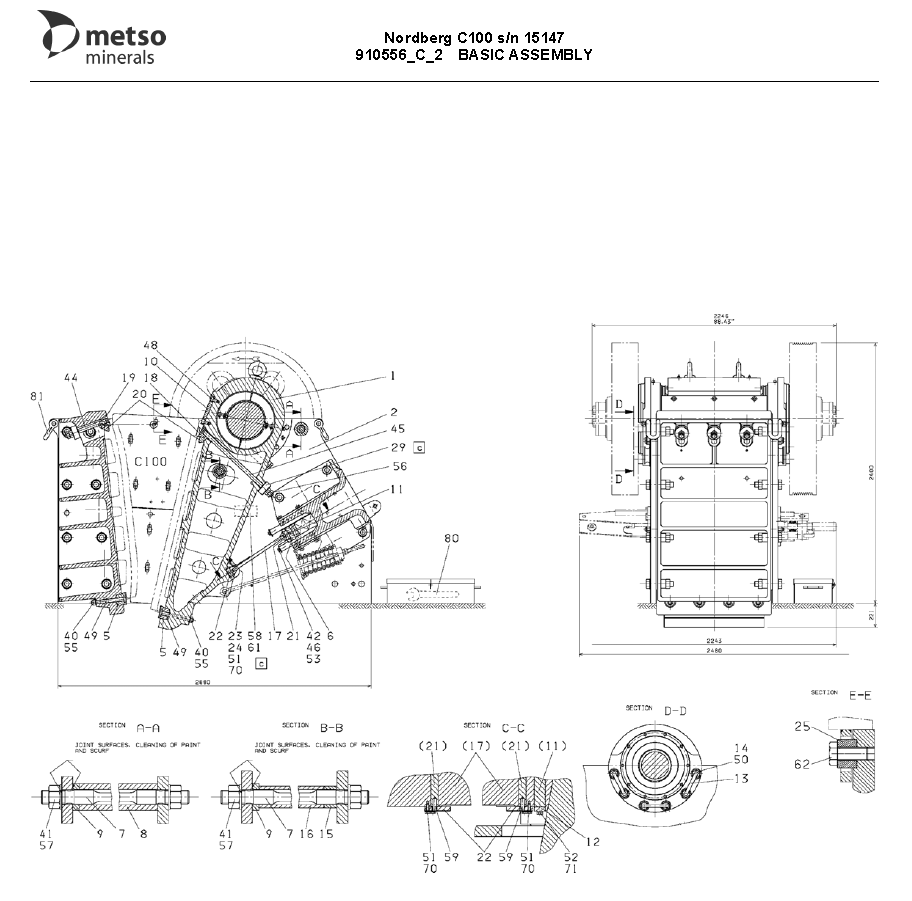

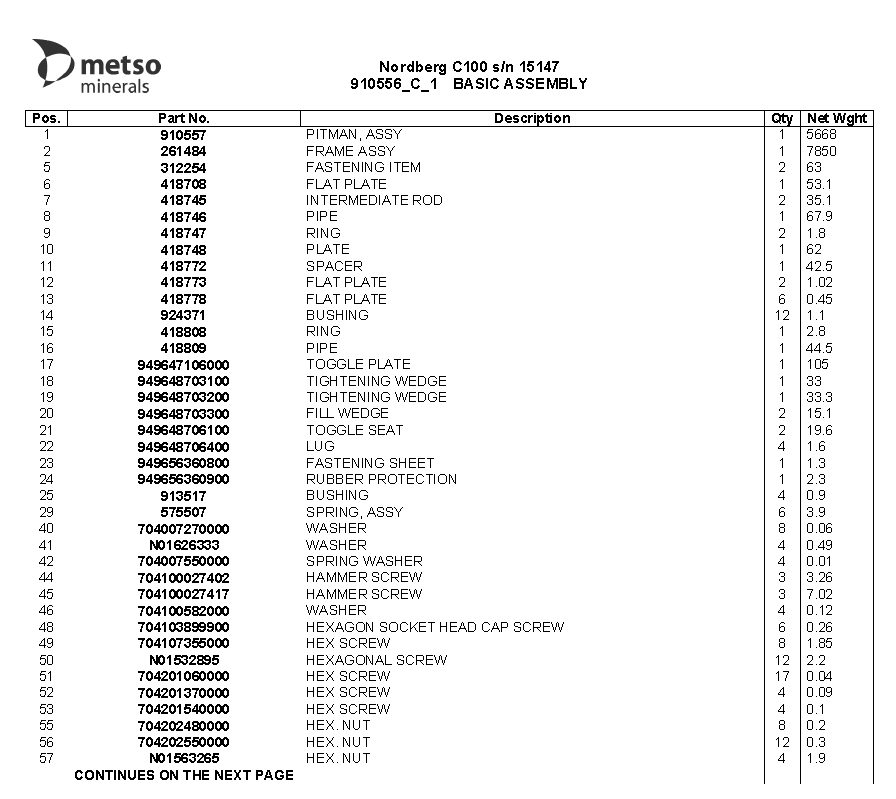

Basic Assembly of C100 PN#910556

The assembly of the Metso C100 crusher1 can be overwhelming. Understanding its components is crucial for efficient maintenance and operation.

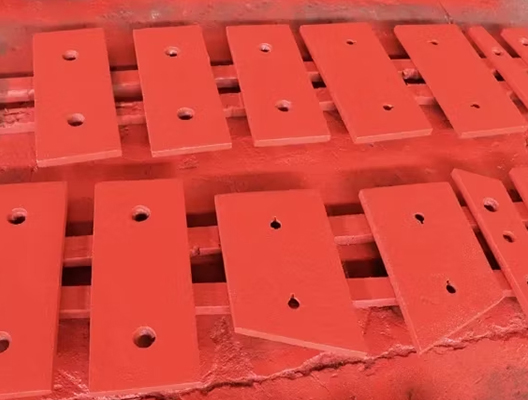

The basic assembly2 of the Metso C100 crusher1 comprises crucial parts like the pitman3, eccentric shaft4, bearings5, and toggle plate6. Each component plays a significant role in the crusher's functionality and efficiency.

It's not common for operators to purchase an entire Metso C100 assembly since it would mean acquiring a whole new machine. Instead, focusing on individual components for maintenance or replacement is more practical.

What are the key components of the Metso C100 assembly?

The Metso C100 crusher1 assembly is complex, and neglecting any part can lead to inefficiency and breakdowns.

The key components of the Metso C100 assembly include the pitman3, eccentric shaft4, bearings5, and toggle plate6. These parts are essential for the crusher's operation, ensuring the crushing process runs smoothly and effectively.

To dive deeper, the pitman3 arm in the Metso C100 is crucial for transferring motion from the eccentric shaft4 to the crushing zone. It acts like a lever and is subject to significant wear and tear. The eccentric shaft4 provides the motion necessary for the crushing action, while bearings5 support the shaft's rotation, ensuring smooth movement. The toggle plate6 acts as a safety mechanism, preventing damage from uncrushable material. Each part must be checked regularly for wear and replaced when necessary. Understanding their function helps in troubleshooting issues and ensuring optimal performance.

Why focus on individual components rather than the entire assembly?

Buying the whole assembly isn't cost-effective. Understanding and maintaining individual components saves money and improves efficiency.

It's more practical to focus on individual components rather than buying a complete assembly. Regular maintenance and replacement7 of parts like the pitman3, bearings5, and toggle plate6 ensure the crusher operates efficiently and prevents costly downtime.

When diving deeper into why focusing on individual components is beneficial, consider the cost-effectiveness8. Purchasing the entire Metso C100 assembly is akin to buying a new machine, which is not financially sensible for most operators. By focusing on individual components, operators can maintain the crusher's functionality without incurring massive expenses. Regular checks and timely replacement of worn-out parts, such as bearings5 and toggle plate6s, can prevent breakdowns and extend the machine's life. This approach also allows operators to customize maintenance schedules according to the component's wear rate, optimizing the machine's performance.

Conclusion

Understanding the Metso C100 crusher1 assembly and focusing on key components ensures efficient, cost-effective maintenance and operation.

Explore this link to understand the applications and benefits of the Metso C100 crusher in various industries. ↩

Explore this link to understand the essential parts of the Metso C100 crusher, crucial for efficient maintenance and operation. ↩

Learn about the role of the pitman in transferring motion and its importance in the crusher's operation. ↩

Discover how the eccentric shaft contributes to the crushing action and its significance in the crusher's efficiency. ↩

Understand the role of bearings in supporting the shaft's rotation and ensuring smooth operation of the crusher. ↩

Find out how the toggle plate acts as a safety mechanism and its role in preventing damage to the crusher. ↩

Regular maintenance and replacement ensure the crusher operates efficiently and prevents costly downtime. ↩

Purchasing the entire assembly is costly; focusing on components maintains functionality without massive expenses. ↩