Uncategorised

5. How to find a suitable crusher wear parts manufacturer?

Finding the right supplier for your crusher wear parts can be frustrating. The wrong choice leads to costly downtime. I will show you how to find a reliable partner.

The best way to find a suitable manufacturer is by providing them with the exact part number. This simple piece of information ensures you get an accurate quote quickly and receive the correct part, eliminating guesswork and costly delays in your operation.

Finding a great manufacturing partner is about more than just a low price. It's about building a relationship that keeps your crushers running efficiently. Getting the right parts on time is crucial for your business. So, let's start with the most important step in this process. This first step will save you a lot of time and money down the road.

What is the most important information to give a manufacturer?

You need a quote, but the constant back-and-forth emails take forever. These delays are costing you production time and money. The solution is simple: give them the one thing they need for a fast quote.

The single most important piece of information is the part number. With the part number, an experienced manufacturer can immediately identify the exact wear part you need. They can check their drawings and give you a precise quote without any delay.

I've been in this business for a long time, and the part number is king. It removes all guesswork. It acts like a universal language between you, the quarry owner, and me, the manufacturer. I've seen so many orders get delayed because of a missing part number. A customer in Indonesia once sent me photos of his jaw plate, but the angles were tricky. We spent a whole week emailing back and forth just to confirm the dimensions. If he had the part number at the beginning, he would have had his quote in an hour and his parts much sooner. The part number is linked directly to a technical drawing that has every detail: dimensions, weight, material specifications, and any special requirements. It is the fastest path to getting your machine back to work.

Why Part Numbers Matter

The part number is a unique code. It tells the manufacturer everything they need to know. It's like a fingerprint for your specific crusher part1. When you provide it, you are guaranteeing that the part you order will fit perfectly. There is no room for error or misunderstanding.

The Fast Track to a Quote

Think about the time you save. Without a part number, we have to ask you many questions. We might ask for photos or measurements. This process takes time. With a part number, the process is instant.

| Process Stage | With Part Number | Without Part Number |

|---|---|---|

| Initial Contact | You provide the part number. | You describe the part or send photos. |

| Identification | We find the drawing in seconds. | We email back and forth to clarify. |

| Quotation | You get a quote within hours. | It could take days to get a quote. |

| Accuracy | 100% guaranteed fit. | Risk of ordering the wrong part. |

How can you find the part number if you don't know it?

You need a replacement part, but you have no idea what its number is. Your machine is down, you're losing money, and you feel stuck. Don't worry, there are several simple places to look for it.

First, check the old, worn part for a cast or stamped number. This is the easiest way. If you can't find it or it's unreadable, look in your crusher's original parts manual. If you don't have the manual, a good manufacturer can help you.

Finding that number is your top priority. It solves most of your problems immediately. I always tell my customers to start with the physical part itself. Over the years, I've learned that a little bit of effort here saves a lot of headaches later. If you can't find it, don't give up. There are other ways, and a good supplier will be patient and help you through them. The goal is to be 100% certain before we start making your part. A wrong part is useless to you and a waste of money and resources for everyone. Let's look at these methods in more detail.

Inspecting the Worn Part

This is the most direct method. Manufacturers often cast the part number directly onto the part itself. You might need to clean the part to find it. I recommend using a wire brush and some water. The number is often hidden under layers of dust, grease, and rock dust. Look on flat surfaces, along the edges, or near mounting holes. Sometimes it's a series of numbers and letters. Take a clear photo of it to send to your supplier.

Using Your Equipment Manual

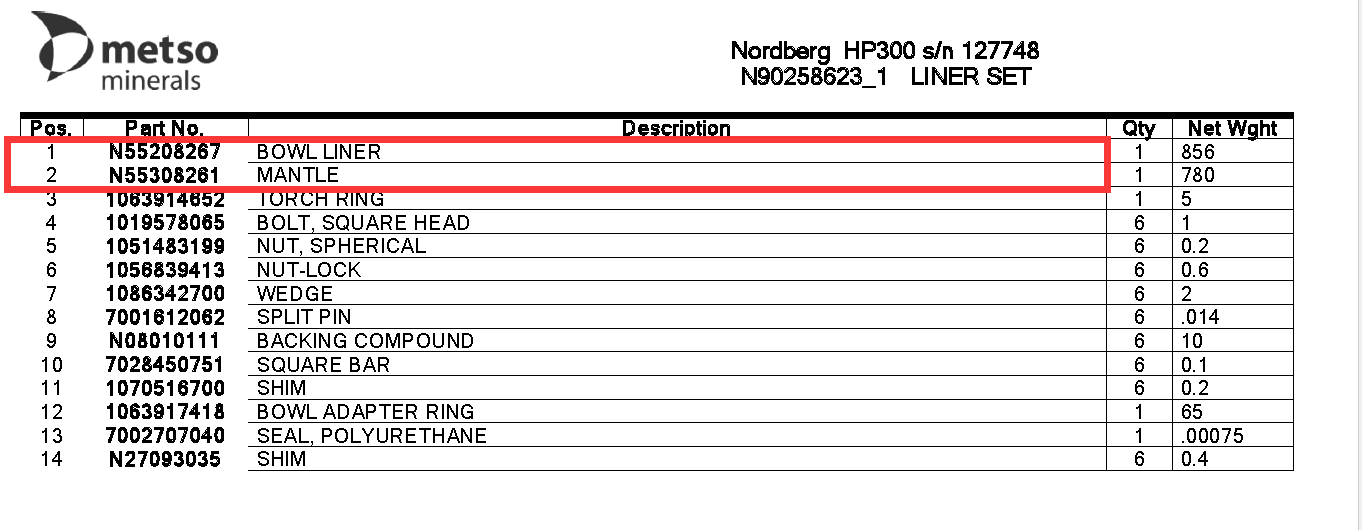

Your crusher came with a user manual and a parts manual. The parts manual is a goldmine of information. It contains exploded-view diagrams2 of your machine. Every single part is shown with a number pointing to it. You can find your part in the diagram and then look up its official part number in the corresponding list. If you've lost your manual, sometimes you can find a digital PDF version online by searching for your crusher's brand and model.

Letting Your Supplier Help

If you've tried the first two methods and have nothing, a good supplier can still help. This is where our experience comes in. You can provide us with the key information about your machine. We need the crusher brand (e.g., Metso, Sandvik, Telsmith), the model (e.g., HP4, GP300S, J-1175), and the serial number if you have it. We have a large database of drawings from over 40 years in the business. We can usually find the part for you. We might send you a drawing and ask you to confirm a few key measurements to be absolutely sure.

| Method | What to Do | Pros | Cons |

|---|---|---|---|

| Check the Part | Clean the old part and look for a cast number. | Fastest and most accurate method. | Number may be worn off or unreadable. |

| Check the Manual | Find the part in the diagram and list. | Very reliable and provides official number. | You might not have the manual. |

| Ask Supplier | Provide crusher brand, model, and serial number. | Uses expert knowledge and databases. | Can take more time; may require you to measure. |

What can you do with no part number, no manual, and an unknown model?

You have an old machine that works hard, but it has no documentation. You think it's impossible to find parts for it. A skilled and experienced manufacturer can still help you get what you need.

Even without any numbers or manuals, you can still get the right part. You will need to take detailed measurements of the old part. A professional manufacturer can provide a checklist or a blank drawing showing the critical dimensions they need to identify or produce it.

This happens more often than you think, especially in regions with a lot of older, second-hand equipment. Don't think your machine is scrap just because you can't find a part number. We call this "reverse engineering3." It requires skill and experience, but it's a service that a dedicated partner should offer. I remember a client in Peru who had a 30-year-old cone crusher from a brand that no longer exists. No manual, no numbers, nothing. He sent us his old, broken bowl liner. We carefully measured every angle and dimension. From those measurements, we created a new technical drawing. We then manufactured a new part for him. It fit perfectly, and he was back to crushing stone in just a few weeks. This is what a true manufacturing partner does.

The Power of Measurement

Accuracy is everything here. You will need some basic tools like a heavy-duty tape measure and maybe a caliper for smaller details. We will guide you. We can send you a simple drawing that shows exactly where to measure. You just fill in the blanks. The more information you can give us, the better. Photos from multiple angles alongside the measurements are also very helpful.

Reverse Engineering Your Part

Once we have your measurements, our engineers get to work. They use the data to create a new, professional CAD (computer-aided design) drawing. We will send this drawing back to you for a final confirmation. This step is very important. It ensures that we both agree on the final product before we start pouring any metal. It's a collaborative process that guarantees success.

What We Need From You

The key measurements depend on the type of part. Here is a simple guide to what we usually need for the most common wear parts.

| Wear Part | Key Measurements Needed |

|---|---|

| Jaw Plate | Overall length, overall width, thickness, number and shape of teeth, location of bolt holes. |

| Mantle | Top diameter, bottom diameter, height, weight, profile shape (e.g., fine, medium, coarse). |

| Bowl Liner | Top inner diameter, bottom inner diameter, height, weight, locking mechanism details. |

| Blow Bar | Length, width, height, location and size of bolt holes, overall weight. |

How do you choose a manufacturer once you have the part number?

Many factories can offer you the same part number. Their prices might even be similar. So how do you know who to trust with your money and your quarry's uptime? Look for a few key signs of a quality partner.

Look beyond the initial price. A good manufacturer has deep experience with major brands, understands material science4 like high manganese steel, and can show you real case studies. They should communicate clearly, be responsive, and act like a partner, not just a seller.

Once you have the part number, the real search begins. The cheapest option is often not the best value. A part that costs 20% less but wears out 50% faster is a bad deal. It will cost you more in the long run due to replacement costs and, more importantly, lost production from the extra downtime. I have built my business on this principle. We focus on providing the best possible value, which means creating parts that last. We are not just selling steel; we are selling uptime and peace of mind. Your goal is to find a partner who understands this, someone who is invested in your success.

Judging by Experience

An experienced manufacturer knows the small details that matter. We have over 40 years of experience matching parts for brands like Metso, Sandvik, and Symons. This means our drawings are tested and proven. Our parts fit correctly the first time. An inexperienced factory might use a generic drawing that is not quite right, which could cause installation problems or poor performance.

Material Matters Most

Not all high manganese steel is the same. The specific "recipe" or alloy composition makes a huge difference in how long the part lasts. We use different blends, like Mn13Cr2, Mn18Cr2, and Mn22Cr2, depending on your needs. I always ask my clients what kind of rock they are crushing. Hard, abrasive granite needs a different manganese blend than softer limestone. A good manufacturer will have this conversation with you to ensure you get the best material for your specific job.

Service That Supports You

A great partner does more than just take your order. They help you. As I've mentioned, we help you identify parts when you don't have the information. We also offer a one-stop service for other spare parts, like bearings, seals, and shafts. We understand the challenges of running a small or medium-sized mine. We are here to make your life easier and your operation more profitable.

| Evaluation Criteria | What to Look For |

|---|---|

| Experience | How many years in business? Do they specialize in your crusher brand? |

| Material Quality | Do they offer different manganese steel grades? Can they advise on the best material? |

| Technical Drawings | Do they have a large library of accurate drawings? |

| Case Studies | Can they show you examples of their work with customers like you? |

| Communication | Are they responsive, clear, and helpful? |

| Full Service | Do they only sell wear parts, or can they supply other spare parts? |

Conclusion

Finding the right manufacturer starts with the part number. But true, long-term value comes from a partner's experience, material quality, and dedicated support. Choose a partner who helps you succeed.

Learn how part numbers uniquely identify parts, ensuring you get the exact match for your equipment. ↩

Discover how exploded-view diagrams help you identify and order the correct parts for your crusher. ↩

Understand how reverse engineering can help you obtain parts for older equipment without documentation. ↩

Discover how understanding material science can lead to better-performing and longer-lasting crusher parts. ↩